Executive summary

The iron and steel industry is the largest energy consuming manufacturing sector in the world. In 1990, its

global energy consumption was estimated to be 18-19 exajoules (EJ), or 10-15% of total annual industrial

energy consumption. The associated CO2 emissions are estimated to be 1425 Mt. In 1995 this amount

increased to 1442 Mt CO2, equalling about 7% of global anthropogenic CO2 emissions.

Before an international regime for Joint Implementation (JI) or the Clean Development Mechanism (CDM)

can be implemented, the problem of setting baselines needs to be solved in a satisfactory way.

This report examines the possibilities for establishing multi-project baselines in the iron and steel sector

and is based on a general assessment of the iron and steel sector with examples from India, Brazil and

Poland.

The report concludes that it is possible to define multi-project baselines in the iron and steel sector

using standardised energy intensities for different production routes. The standardised baselines would

apply to the production of crude steel (the intermediate product in steel making), as final products differ in

energy intensity. Baselines may also need to take the product mix and quality of coal and iron ore inputs

into account when determining the credits available for potential projects in the sector. Given the

international homogeneity of the sector, it is suggested that standardised energy intensities could apply to

similar projects across countries.

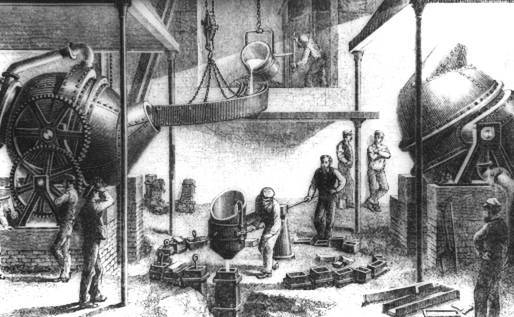

1.1 The iron and steel process and potential for emission savings

The iron and steel making process may be divided into five different steps:

1. treatment of raw materials;

2. iron making;

3. steel making;

4. casting; and

5. rolling and finishing.

Emissions (predominantly CO2) from iron and steel production are caused by the combustion of fossil

fuels, the use of electrical energy and the use of coal and lime as feedstock.

There are different production routes with substantially different energy intensities in which steel can be

manufactured from iron ore or scrap. However, as step 2 (iron making) is the most energy intensive, steel

production from minimills is generally much less energy and GHG intensive than steel production from an

integrated steel mill.

Production is primarily undertaken through three different processes:

COM/ENV/EPOC/IEA/SLT(2001)5

6

• Integrated Steel Plants (ISPs);

• Scrap based Electric Arc Furnaces (scrap-EAF); and

• Direct Reduced Iron Electric Arc Furnaces (DRI-EAF).

The dominant steel production processes are the integrated steel mill (where steel is produced from iron

ore by following steps 1 - 5 above) and the minimill (where steel is produced from scrap steel or substitutes

by following steps 3 - 5 above).

The greenhouse gas emissions associated with iron and steel production depend on how much energy is

used and the greenhouse gas intensity of that energy. Energy intensities are used as the standardised

component of emission baselines instead of CO2 intensities because there is lower variation in the former.

Using energy intensities avoids having to effectively proscribe which fuel should be used, the relative

proportions of fuel and electricity and the GHG-intensity of electricity used in the steel production process.

There are a number of potential energy-related JI/CDM project types in the iron and steel sector. These

include:

• increasing the energy efficiency of steel production (e.g. by installing more efficient equipment

and/or implementing good housekeeping measures);

• changing the manufacturing process (e.g. by installing new equipment); or

• changing the fuel used for the direct reduction of iron (e.g. from coal to gas).

1.2 Benchmarking versus technology matrix

Several methods for multi-project baseline development have been described in the literature. This analysis

considers two: benchmarking (setting a standardised value for energy use for a particular process) and

technology matrix (setting a standardised value for energy use for a particular technology).

The differences in the environmental credibility (additionality requirement) between the two baseline types

are relatively small. However, the data requirements for the latter are large, particularly for the inclusion of

technologies that do not cause step change difference in performance. Such data requirements translate into

substantially higher costs for development. Given the increased transparency possible with a benchmarking

approach and the difficult data demands of the matrix approach, a baseline based on standardised energy

values for different production processes (“benchmarks”) is recommended.

1.3 Stringency of baselines

This report proposes setting different standardised energy intensities for the different major steel

production routes, i.e.:

• Integrated Steel Plants (ISPs);

• Scrap based Electric Arc Furnaces (scrap-EAF); and

• Direct Reduced Iron Electric Arc Furnaces (DRI-EAF).

The benchmark value in the benchmarking approach, or the standard set of technologies in a technology

matrix, can be determined based on various assumptions. These different assumptions result in baselines

that are more or less stringent.

COM/ENV/EPOC/IEA/SLT(2001)5

7

The levels of stringency studied are:

1. best practice world wide level;

2. world wide average level (with and without an autonomous energy efficiency improvement);

3. country level (average and “better than average”); and

4. a “graduated crediting” level, which takes into account both technological best practice and country

average levels.

This analysis evaluates the stringency options against a set of selected criteria, including environmental

additionality, potential volume of projects, transparency and verifiability and baseline costs (Table ES).

This analysis indicates that any particular baseline approach involves trade-offs between factors, with no

single option emerging as a unique “best” solution in all cases.

However, for refurbishment of existing plants, a benchmark on the world-wide average is considered to be

a good trade-off between environmental credibility and the potential volume of projects.

For new capacity, a benchmark based on the world-wide best practice (which is equal to marginal

technology addition) is considered the most suitable.

1

.4 Potential for JI/CDM projects

Potential project volumes under each level of stringency are quantified in three case study countries. The

analysis suggests that the likely number of that would meet minimum standards is not high, whichever

approach is used.

One potential method to increase the potential volume of projects while still preserving the environmental

credibility may be to provide credit in a progressive way. For example, refurbishing plants so that they

perform better than the country or production process average may result in these projects being eligible

for some credits even if the refurbished performance does not reach BAT standards. Shortening the

emissions timeline for such “intermediate level” projects would have a similar effect on the number of

credits they generate.

1.5 Data availability and other issues

In general, data availability is limited with respect to the iron and steel sectors. However, the detailed

research undertaken for the India case study suggests that the necessary data may be available, but that

their collection may require additional research (and cost).

It is difficult to give general rules regarding emission timelines, mainly because the average lifetime of an

industrial technology is very difficult to determine, as it can vary substantially from site to site (depending

on its operation, maintenance and thus, indirectly, on the availability of funds). This also means that the

current age of the stock is therefore not considered to be a useful indicator for determining the additionality

of CDM/JI projects.